HIRO 160 FLEX

The all-rounder

So there you have it: The 160 FLEX from HIRO. A model for customers with the highest standards and the desire to take advantage of the wide range of options. This stairlift is impressive across the board for indoor use: The finest German craftsmanship in our in-house production facility in beautiful Westphalia guarantees sophisticated technology “Made in Germany.” Our highlight, the patented traction drive, is unique and offers numerous advantages. Find out why you’ve come to the right place and what a fully equipped HIRO stairlift can offer right here. Firsthand.

Description

The drive makes the difference

The HIRO 160 FLEX features our patented traction technology. This drive offers numerous advantages for you as a HIRO stairlift user: Thanks to the combined friction force of four drive and guide rollers (two drive and guide rollers for the 160 AIR), our stairlifts navigate the tightest curves on the market with exceptional safety and stability. This leaves you more space on the stairs. Using this roller system also makes it possible to provide additional stability with the help of a two-tube track system. Whether on curves or on steep stairs, stability is always guaranteed. Furthermore, the stairlift is prevented from slipping.

But the biggest advantages are as ingenious as they are easy to understand, especially when, as in our case, high-performance elastomer (the material of the rollers) meets stainless steel (our track). The ride is silent and smooth, the rollers experience minimal wear, are temperature-resistant from -40 to +80 degrees Celsius, and require virtually no maintenance. Not only do we produce cleanly, but thanks to traction, you don’t need to grease, oil, or lubricate the drive or track. It couldn’t be more.

In this video, you can see how the drive system works on the HIRO 160 FLEX, allowing you to climb stairs safely, stably, and smoothly. For more information about this unique technology, see the manufacturer’s warranty or contact your personal specialist advisor.

Highlights

- Interior

- straight staircase

- curved staircase

- Made in Germany

- patented traction drive

- electric footboard

- integrated emergency call system

- Diagnostic display

- increased load-bearing capacity

- Special fastenings

- configurable design

- extensive color selection

- Manufacturer’s warranty

- CE marking

Features and technical functions

- Diagnostic display

- continuously adjustable backrest

- electric swivel seat

- electric footrest

- joystick control

- lubrication- and oil-free operation

- optional footrest extension

- space-saving parking position

- hand-padded seat cover

Security

- Safety belt with FIDLOCK® magnetic closure and immobilizer

- contact sensors on the drive unit and footboard

- acoustic warning signal

- integrated emergency call system in the armrest (activation required)

- encryption against unauthorized use

- CE certification

- HIRO quality management

Your stairs remain as they are

Thanks to our special fastening systems, we can offer you a wide range of options without having to drill or glue your stairs. Depending on the structural conditions and your personal preferences, we will find the best solution so that your stairs can remain as they are.

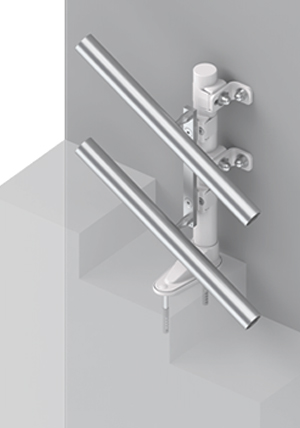

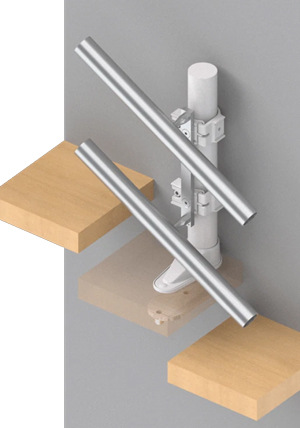

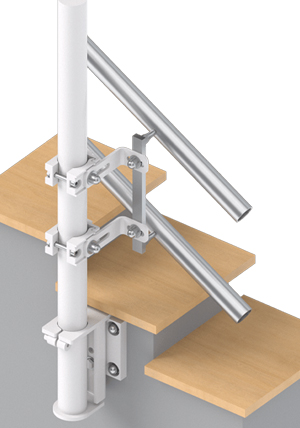

01 – Attached to the step

The supports are screwed onto the steps.

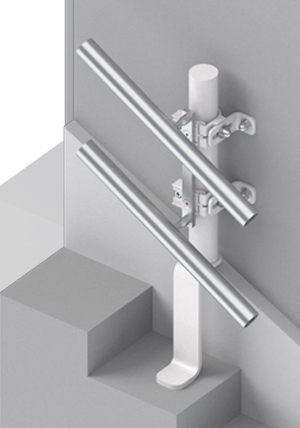

02 – Attached to the step and supported laterally

Attached to the step and supported laterally

03 – Placed on the step and supported laterally

The supports are placed on the steps and simply attached to the wall. No drilling into the steps is necessary!

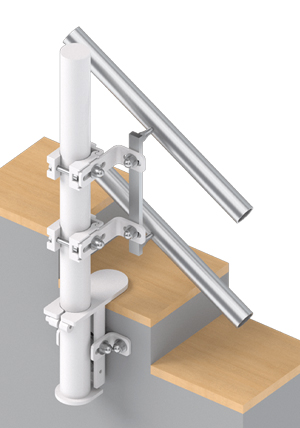

04 – Z-support over stair stringer

The supports are attached to the wall above the stair stringer. No drilling into the steps is necessary!

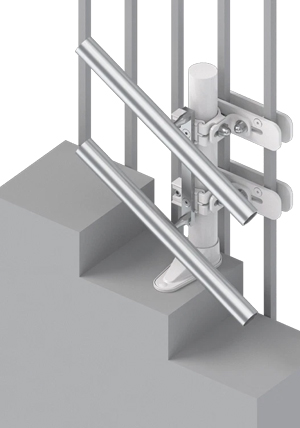

06 – Harp attachment

The supports are placed on the steps and attached to the stair harp using a clamp. Drilling into the steps is also not necessary.

09 – Supports erected and attached to the beam

The supports are placed on the steps and connected to the joist. The joist is attached to the side of the stairs. Drilling the steps is also not necessary here.

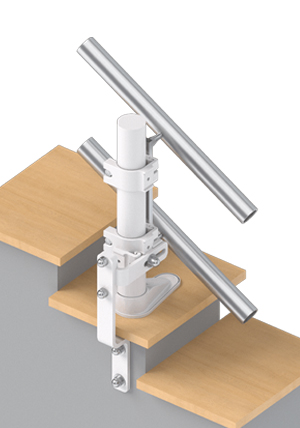

10 – Supports with clamp fastening

The supports are securely attached to the steps using clamps that slide onto the steps, without drilling. A stable hold is ensured by tightening a screw underneath, similar to a screw clamp.

11 – Counter plate fastening

The supports are attached to the steps using a counter plate.

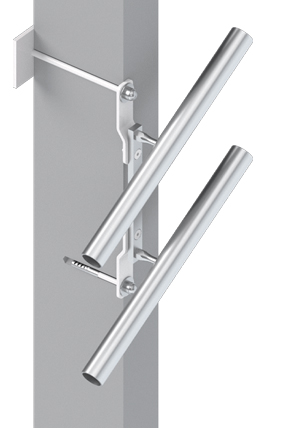

20 – Wall fixing in concrete

The deck is attached directly to the concrete wall. No drilling into the steps is necessary!

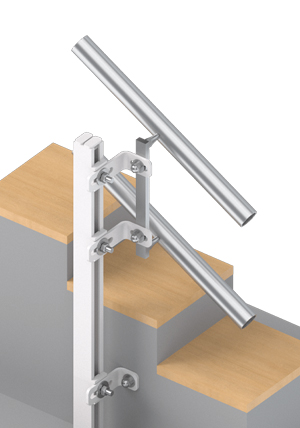

13 – Supports in the stairwell with double C-profile

C-profile support attached to the floor in the stairwell with lateral support on the stairs. No drilling is required for this type of support.

14 – Supports in the stairwell

A support is attached to the floor in the stairwell with additional screw connections on the side of the stairs. Drilling into the steps is not necessary!

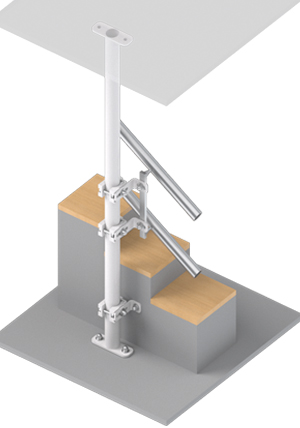

15 – Telescopic supports

The supports are placed between the floor and ceiling. The deck is attached to them on both sides. This eliminates the need to drill holes in the steps.

16 – Support bracket

The support bracket located in the stairwell is screwed to the stair stringer and positioned on the side of the tread. No drilling into the treads is necessary.

17 – Cheek attachment

The supports are attached directly to the stair stringer. Drilling into the treads is not necessary!

19 – Wall mounting with through screws

The track is attached directly to the wall with a through-bolt. No drilling into the steps is necessary.

21 – Wall mounting wall anchor

The deck is attached directly to the wall with a wall anchor. No drilling into the steps is necessary.

Additional information

| Ράγα Κίνησης | |

|---|---|

| Μέγιστο Φορτίο | |

| Τροφοδοσία ρεύματος | |

| Ταχύτητα |